Historic Ceramics

Introduction

Ceramic artifacts are abundant on nearly all historic archaeological sites. These items range from simple jugs and plates, to delicate buttons and fine china, and everything in between. 25SW49 is no exception to this. Ceramic sherds of several types were excavated from the site, including ironstone, stoneware, whiteware, pipe fragments, and prosser buttons. The analysis of these artifacts is broken into three sections. First, the horizontal and vertical distribution of ceramics throughout the site is discussed. Second, a major effort was made to refit sherds whenever possible. This process and the implications are discussed in this section. Third, an overview of the ceramic ware types and vessel types found at the site and the meaning of these is discussed in the third section. The goal of this chapter is to understand the types of ceramic artifacts recovered during excavation and their distribution across the site.

Ceramic Artifact Distribution

By Kyle Baxter

Introduction

During the summer of 2005, the University of Nebraska–Lincoln Archaeological Field School carried out excavations at the Beaver Creek Trail Crossing Site (25SW49). A total of 41 test units were excavated on the eastern and western sides of the creek (Figure 3.1). However, the two test units on the western side of the creek contained no ceramic artifacts, leaving 39 units for ceramic spatial analysis (Figure 3.2). This paper will discuss both the vertical and horizontal spatial distribution of these ceramics. The second section will discuss the methods used in this analysis. The third section will discuss the results, followed by an interpretation of the distributions and conclusions.

Methods

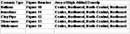

The first step in analysis was to complete a preliminary classification of all the artifacts recovered. From this data, an artifact catalogue was created. Within the catalogue, five types of ceramics could be identified. These were buttons, ironstone, clay smoking pipes, whiteware, and stoneware. However, there were several sherds that had been heat altered. These were not considered for analysis since the exposure to high temperatures rendered them unidentifiable as to ware type. Using the artifact catalogue, as many of the ceramics as possible were classified into one of these types. Classifications were also rechecked for clarity and accuracy in description.

Once this was done, a shapefile was created using the grid points of the test units. The grid was created with an arbitrary datum that will later be tied into the UTM system. This file depicts all of the test units at the site. In order to accomplish this, it was necessary to find the corner points of each unit using the grid set up prior to excavations. From there, the points were placed within ArcGIS and each of the test units digitized into the file. Each of the units was labeled by test unit number within the shapefile attribute table. This would allow the shapefile to be connected quickly and easily to a table in .dbf4 format using the join function. The biggest drawback of this method is that when the user quits ArcGIS any joins created will automatically be lost. Also, the join function combines information based on attribute. Since the shapefile had the test unit numbers within its attribute table, any table combined with it would need the same data. However, the combination is conducted on a one-to-one basis. This means that there can only be one of each unit number in the table. If there is more than one, a single row will be kept, while the others will be disregarded. These factors had to be taken into account before it was possible to proceed with the analysis.

The next step was to create the tables that would be combined with the shapefile. Because of the nature of the join function, it was necessary to create tables that contained one row for each test unit. To accomplish this, the artifact catalogue was collapsed so that each row contained one test unit and the number of artifacts for each ceramic type found within it. There were nine tables created in all — one for each of the seven levels, one for the features, and one for the test units as a whole.

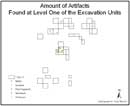

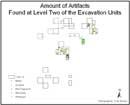

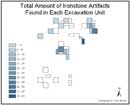

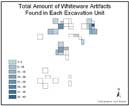

The tables were used with the join function in order to create a shapefile that depicts the number artifacts found in a certain area. The seven excavation levels and features were mapped as dot density, so that all of the artifact types could be mapped together. The horizontal data was broken down into five different maps, each displaying the amount of a ceramic type throughout an entire test unit. In order to enhance the display, a graduated color scheme was used.

Results

This section will discuss the distribution of artifacts found at 25SW49. For simplicity, this will refer to the excavation units that contained historic ceramic artifacts, ignoring the two that did not. The vertical distribution of artifacts will be discussed first, followed by the horizontal, with the features discussed last.

The figure number, distribution of artifacts, and the most common ceramic type for each level are shown in Table 3.1. The second level contained the most ceramic artifacts, with each subsequent level containing fewer than the previous with the seventh level only containing one ceramic sherd. It should also be noted that the second level contained a distribution reflecting a diagonal line starting in the center of the excavated test units and continuing out into the northeast. In general, ceramic artifacts tend to appear in the same places within the site; the center, north-central, and northeast. In several excavation levels, there were also ceramics found in the northwest portion of the excavation of the site. However, this area did not contain as high a density as the others and was not considered as significant.

The horizontal distribution represents the amount of artifacts belonging to the five different ceramic types within each excavation unit. Table 3.2 depicts the figure number and the areas of high artifact density for each type. In general, all of the ceramic types are seen in the same areas. They take on the form of two diagonal lines, seen best in Figures 3.11 and 3.12 respectively. The northern line starts in the northeast and continues into the north-central portion of the site, while the southern line starts in the northeast and continues into the center. It should be noted that the southern line is in the same area as that noted in the second excavation level. It must be noted that this pattern of diagonal concentration lines is only a preliminary observation. More excavation needs to be conducted in the northwest, south, and southeast areas of the site to confirm these patterns. However, this pattern does form the basis for further research questions in subsequent field seasons.

Feature 5

The spatial distribution of features can be seen in Figure 3.15. A high density of artifacts can be seen in the northwest portion of the site. This occurred at Feature 5 from which a large number of buttons were found with moderate numbers of ironstone, pipe fragments, and whiteware artifacts. There is a smaller distribution of artifacts occurring in the northeast, which is primarily composed of ironstone.

Interpretations

From the different distributions discussed above, it is possible to see a pattern of two diagonal lines of concentrated ceramic artifacts (Figure 3.16). The northern-most of these two lines starts in the northeast of the site and continues on into the north-central, while the southern line starts in the northeast and goes to the center. While additional testing is necessary to confirm these patterns, these two lines could represent the approximate limits of occupation as a possible footprint for at least one building. This pattern would be indicative of people breaking a ceramic object and discarding it outside of their living space. This may take place at the door, window, or porch of a structure at the settlement. A house with an additional wing, believed to have been in the vicinity of the occupation lines, was photographed in 1866 (Waterman 1927:33). This wing was similar to a set of "lean-tos" which would have served as temporary or special function structures remaining partially exposed during the winter. The distribution seen throughout the levels of excavation seems to confirm this interpretation. The appearance of artifacts within the same areas throughout all seven levels would imply that this pattern had been utilized for the duration of occupation.

The only feature to contain a large amount of ceramic artifacts was Feature 5, interpreted as refuse pit, with a large amount of debris (Figure 3.16). This pit showed signs of burning, as if the refuse was periodically set on fire. This function explains the large number of artifacts found within the feature.

Discussion

Using the ArcGIS platform, maps depicting the spatial distribution of definable ceramic artifacts at the Beaver Crossing site were created. From these maps, a pattern of concentrations in the form of two diagonal lines was generated. The first concentration started in the northwest and continued on into the north-central while the other started in the center and went through the northeast portion of the site. These would be indicative of a limit of occupation near the edges of a structure. The vertical distribution across the site would suggest that this pattern had occurred over the entire occupation. Feature 5, which contained more identifiable ceramic artifacts than any other feature, appears to have been used as a refuse pit. More sampling is needed in areas to the east and southeast to confirm the extent and patterning of these concentrations.

Ceramic Refits

By Jennifer McCollough

Methods

All ceramic fragments from 25SW49 were examined to find as many sherds that refit as was possible. This was accomplished by examining ware type, thickness, glaze type and color, patterns embossed and glazed, and other factors of each sherd. Also simple trial and error played a role in the process. Only those sherd that were almost certainly true fits were glued together. Sherds that refit within a single provenience were simply glued and let dry on a bed of rice. This type of refit is referred to as an internal refit. Sherds that refit between proveniences had a small tag with their provenience number attached with top and bottom layer of a 20 percent acetone solution of B-72. However, for ease of labeling and appearance of the reconstructed vessel, spalls were only labeled if their provenience differed from that of the larger piece into which they fit. Also, a label that crosses a break between two pieces indicates that the sherds are from the same provenience. Additionally, in the case of one dish, the sherds from one provenience were the only unburnt pieces. Thus, the unburnt section had one label affixed to it and a note is made below in the discussion of that vessel. Every attempt was made to place the labels on the exterior, or lower, surface of the vessel; however, in cases where no portion of the sherd was showing on the exterior, a small label was placed on the interior, or upper, surface. In a few cases, storage or labeling concerns dictated that sherds that refit between proveniences were not actually glued together. For example, the handle of the stoneware jug would have been difficult to store without it breaking off again. The state of the sherds of a teacup in another provenience would have made labeling it for refitting between proveniences extremely difficult. In both cases a note is made in the discussion of those vessels or proveniences.

Refits between proveniences

Vessel 1

Vessel 1 is a white glazed ironstone oval dish, possibly a vegetable dish, with a molded Berlin Swirl design. The bottom contains an impressed maker's mark, a pattern patent mark, and the importer's mark. The dish contains sherds from proveniences 0168, 0169, 0176, 0180, 0182, 0186, and 0199. Sherds that did not refit, but are most likely from the same vessel are found in proveniences 0169 and 0153.

Vessel 2

Vessel 2 is a whiteware plate with blue pooling of the glaze. It has a diameter of approximately 20–21 cm. It contains sherds from proveniences 0163, 0169, 0176, 0180, 0188, 0194, and 0195. A piece that did not refit, but may be from the same vessel is found in 0209.

Vessel 3

Vessel 3 is a small whiteware dish with a pink and black under-glaze design and an over-glaze black star design. It is composed of unburned sherds, all of which are from provenience 0062, and burnt sherds from 0151, 0156, 0165, and 0167.

Vessel 4

Vessel 4 is an ironstone plate with a maker's mark on the bottom. It is approximately 19–20 cm in diameter and is possibly the same vessel as 6 and/or 7. It consists of sherds from proveniences 0070, 0084, 0153, 0156, 0157, 0161, 0165, and 0191.

Vessel 5

Vessel 5 is a fragment of the base and footring of an ironstone plate. It contains pieces from 0151, 0156, 0165, and 0167.

Vessel 6

Vessel 6 is a fragment of ironstone plate containing rim and footring pieces that may be the same vessel as 4 and/or 7. It is composed of proveniences 0185 and 0191.

Vessel 7

Vessel 7 is also a fragment of an ironstone plate containing rim and footring pieces. It may be the same vessel as 4 and/or 6. It contains sherds from 0151, 0156, and 0166.

Vessel 8

Vessel 8 is a stoneware jug with an interior brown slip and exterior grey salt glaze. It is composed of sherds from proveniences 0062, 0073, 0080, 0135, 0136, and 0153. The handle in provenience 0122 refits, but was not glued to prevent storage problems.

Vessel 9

Vessel 9 is a small whiteware dish, possibly a saucer with panels and a transfer print design. It contains pieces from 0049, 0182, 0194, and 0198.

Vessel 10

Vessel 10 is the burnt base of a whiteware dish containing the footring. It is composed of pieces from 0201 and 0205. These proveniences were part of feature 5.

Vessel 11

Vessel 11 is a piece of the rim of an ironstone paneled dish, probably a plate, and appears to have been heated. It has sherds from proveniences 0194 and 0199.

Vessel 12

Vessel 12 is the rim of a whiteware plate with a molded edge decoration. It is approximately 18-19 cm in diameter and is composed of proveniences 0123 and 0126. It is probably the same vessel as 13–17.

Vessel 13

Vessel 13 is a fragment, with the footring, of a whiteware vessel and is probably from the same plate as vessels 12 and 14–17. It contains sherds from proveniences 0156, 0166 and 0191.

Vessel 14

Vessel 14 is a fragment of the base of a whiteware dish and is probably from the same plate as vessels 12–13 and 15–17. It has pieces from proveniences 0123 and 0126.

Vessel 15

Vessel 15 is a fragment of the rim of a whiteware vessel and is probably from the same plate as vessels 12–14 and 16–17. It is composed of pieces from 0151 and 0156.

Vessel 16

Vessel 16 is a fragment, with the footring, of a whiteware vessel and is probably from the same plate as vessels 12-15 and 17. It contains sherds from 0151 and 0156.

Vessel 17

Vessel 17 is a fragment of the brink of a whiteware vessel and is probably from the same plate as vessels 12-16. It is composed of sherds from proveniences 0156 and 0191.

Internal Refits

| 0059 — | 2 ironstone |

| 0084 — | 5 whiteware — footrim with an interior molded design |

| 0100 — | 2 whiteware — black band design |

| 0123 — | 3 ironstone — molded design |

| 2 whiteware — possibly same dish as vessel 12 | |

| 5 whiteware — footrim, possibly same dish as vessel 12 | |

| 4 whiteware — possibly same dish as vessel 12 | |

| 0153 — | 4 whiteware — rim, black band design |

| 8 ironstone | |

| 2 ironstone — | rim, Berlin Swirl, possibly same dish as vessel 1 |

| 0155 — | 2 whiteware — possibly same dish as vessel 12 |

| 0156 — | 7 whiteware — rim, molded edge, possibly same dish as vessel 12 |

| 3 whiteware — rim, molded edge, possibly same dish as vessel 12 | |

| 2 whiteware | |

| 2 whiteware — footrim | |

| 3 whiteware | |

| 2 whiteware — footrim, refits but was not glued to sherd in 0151 | |

| 4 whiteware | |

| 9 whiteware — footrim, refits but was not glued to sherd in 0151 | |

| 0166 — | 2 ironstone — rim |

| 0167 — | 5 ironstone — rim |

| 0173 — | 13 whiteware — rim |

| 0179 — | 9 ironstone — footrim |

| 2 stoneware | |

| 2 stoneware | |

| 0182 — | 2 whiteware — heat altered |

| 3 whiteware — heat altered | |

| 2 whiteware — heat altered | |

| 2 ironstone — footrim with molded exterior | |

| 3 whiteware | |

| 9 ironstone — rim of paneled plate with Berlin Swirl molded pattern | |

| 8 ironstone — rim of paneled plate with Berlin Swirl molded pattern | |

| 2 ironstone — footrim | |

| 0191 — | 3 whiteware |

| 0194 — | 2 whiteware — base of a paneled teacup with interior and exterior transfer print |

| 6 ironstone — | rim, paneled plate with Berlin Swirl molded pattern (see White Ironstone China Plate Identification Guide p.66) |

| 0209 — | 2 whiteware — rim of a teacup with the Berlin Swirl molded pattern on the interior |

Ceramic Artifact Analysis

By Samantha Kirkley

Introduction

The following ceramic analysis is generated from the interpretation of artifacts in the collection, including stoneware, ironstone, and whiteware. The focus of the analysis deals with ceramic utilitarian ware and excludes items such as clay pipes and buttons.

Stoneware

During the 1700s, white salt-glazed stoneware was used as elegant tableware in many English homes. However, due to Josiah Wedgewood's development of "true porcelain" in the mid-1700s, stoneware became more commonplace as a utilitarian ware (Greer 1981:17).

Many German and English immigrants brought their stoneware businesses to North America during the 18th and 19th centuries (Greer 1981:18). American stoneware often became a combination of both styles. However, the salt-glaze technique remained consistent. Salt-glaze was one of the most common types of glaze used for utilitarian stoneware in the 1800s. Potters threw or blew salt onto the vessels while in the kilns and the extreme temperatures allowed the salt to bond with compounds in the clay to form a glossy coat (Greer 1981:180). While various colors of clay would have been used for utilitarian stoneware in 19th-century America, many potters favored the lighter clays. The clay was often called "potter's clay," an especially coarse and durable composition capable of retaining its form in extremely high temperatures, as stoneware vitrifies between 1200 and 1400 degrees C (Greer 1981:15).

In the mid-1800s, interior and exterior glazed stoneware vessels became more common. The vessels were durable, leak-proof, acid resistant, and easy to clean. While unsuitable for cooking, the stoneware vessels largely replaced earthenware for the storage of goods both solid and liquid (Greer 1981:16). Potters produced various types of stoneware utilitarian vessels, such as jugs, churns, storage jars, water coolers, milk bowls, and pitchers. Jugs were the most common form of stoneware manufactured in the 1800s. Larger jugs were used to store liquids such as water, hard liquors, vinegar, oils, and syrups, while smaller jugs contained hard liquors, beer, ink, and turpentine (Greer 1981:75).

There are seventy-eight salt-glazed stoneware sherds in the collection. The majority are light gray on the exterior with a brown slip glaze interior. Some are dark brown, but have been heat altered making the true coloring difficult to determine. All of the fragments are from about six to eight mm in thickness.

A partial stoneware vessel has emerged from reconstruction efforts. The vessel fragment is slip-glazed on the interior with dark brown clay, most likely an Albany Type slip (Greer 1981:194). The clay for this type of slip was first extracted near Albany, New York, but became widely produced in the Midwest during the last half of the 19th century (Stelle 2001). The presence of an interior slip-glaze generally dates stoneware to post-1860 (Greer 1981:263). The one shoulder fragment of the reconstructed vessel suggests that it is a semi-ovoid or cylindrical jug with rounded shoulders, probably manufactured after 1860. The true ovoid shape jugs were not produced with any frequency after 1860 (Greer 1981:263). The base is flat and is either round or ovoid. No approximate size of the containers can be determined due to the lack of sufficient reconstructive fragments. The fragments bore no marks to indicate decoration, makers, dates, or size. A handle fragment and a neck and mouth fragment indicate that the vessel was a jug form.

Ironstone

Almost all of the ironstone dishes of the 1800s were produced by potters in Staffordshire, England (Whetherbee 1981:10). Many contributed to the development of ironstone, but Charles James Mason was the first to coin the phrase "ironstone." In 1813, Mason's "Patent Ironstone China" became available to buyers in Europe and America. The name, suggesting robust elegance, attracted many housewives (Whetherbee 1981:13). These first experiments produced a more durable fabric than had been produced previously, but not to the strength of the later ironstone of the 1860s. The earliest ironstone dishes contained flow blue patterns, which in later years were changed to cobalt blue transfer print designs. While many upper class citizens still preferred porcelain, inexpensive ironstone became increasingly popular among lower class households (Whetherbee 1981:15).

While English potters perfected the inexpensive, durable fabric by the 1830s, white ironstone did not appear in the United States until after 1840 (Whetherbee 1981). "[These] were the kind of dishes that could be packed easily and were tough enough to take trail life" (Whetherbee 1981:9). The simplistic beauty and durability of white ironstone dishes have become associated with westward expansion in America in the latter half of the 1800s.

In correlation, this robust white ironstone remains the dominant ceramic type found at the Beaver Crossing site. The collection includes approximately 280 sherds of ironstone; however, these numbers are an approximation as some of the sherds are heat altered and a precise identification is not possible.

Several pieces of ironstone embossed with the Berlin Swirl pattern were found at the site. The Berlin Swirl pattern was first produced by T. J. & J. Mayer in the mid-1840s, but was reissued several times into the 1860s. The Berlin Swirl was not only one of the earliest ironstone patterns, but it was also one of the longest running designs (Whetherbee 1981:39). The Berlin Swirl design has been identified on an oval shaped bowl, an octagonal-plate, and a tea cup. The oval shaped bowl has been partially refitted including over half of the vessel. Measurements of the length and width were difficult to ascertain, as one end and one side are missing. However, the base is mostly complete yielding several distinguishing marks. The impression "Mayer & Elliot" is stamped on the bottom of the vessel near the manufacturer's mark. It reads "manufactured for Chauncey J. Filley St. Louis, Mo." In addition, there is a diamond registry mark on the base that indicates the year in which the design was registered. The design registration for this piece is listed as Dec 18, 1856 (Whetherbee 1996:15). This oval shaped bowl closely resembles that of a vegetable serving dish and was most likely used as such. In addition to the bowl, an octagonal plate sherd further demonstrates the popularity of the Berlin Swirl style at Beaver Crossing. The Berlin Swirl pattern also emerges on several fragments of a tea cup. The fragments consist of rim and foot pieces along with a partial handle.

Two white ironstone 8 ½ in. luncheon size plates void of decoration were identified from the collection. The underside of one plate exhibits the British Royal Arms mark; however, the exact maker's mark cannot be determined due to missing fragments (Whetherbee 1996:13). This thick, plain style of ironstone has been labeled "hotel" ware. In the last half of the 19th century, hotels liked using the more robust, durable ironstone because of its frequent and often rough use. However, Beaver Crossing was technically a road ranch and would not have had any fancy hotels or restaurants like those in established cities. The smaller plate size could have been used in these types of establishments to serve a full plate of food for a specific price without having to use the quantity of food that would have filled a regular dinner plate of 10 ½ in. to 11 in. While there was a steady flow of freight traffic past Beaver Crossing, supplies would still be limited and costly, further justifying such an action by businessmen. The presence of the luncheon sized plates could also mean that the plate size was more common for use on the Plains. The ironstone china was not only durable enough to make the hard trip across the Plains, but the smaller sized plates would have taken up less space in the wagons.

Whiteware

Whiteware was developed in England about 1810 and had become the most common earthenware in America by the 1830s. As its name suggests, whiteware is notably white in color, yet harder than precursory pearlware. Whiteware was generally plain and undecorated, hand painted, or transfer printed (Stelle 2001).

The Beaver Crossing collection contains 233 sherds of whiteware. Again, some of these were heat altered and an exact identification was not possible. One vessel is represented by a small cobalt blue transfer print dish, approximately 6 in. in diameter. The sides are deeper than a regular saucer, yet shallower than a standard soup bowl. The dish, looking at relative size, would have fit between a tea cup saucer and a dessert plate in a standard set of dishes. This size of dish has been called many things, such as a honey dish, as its true function remains a mystery. During the 1800s, this size of dish came with a standard set of dishes (Whetherbee 1981:33). However, the size of dish is not found in standard tableware sets today, which could mean that its function expired over time. The blue transfer print pattern along the rim also remains a mystery after looking in several design books. It appears to be a contemporary style with those of the 1850s, but no identical pattern has been found. The collection also has one paneled, cobalt blue transfer printed tea cup fragment. The pattern is not discernable and no other pertinent pieces have been identified from the sherds to be refitted with the tea cup fragment. There is potentially another blue transfer print tea cup among the whiteware. It is represented only by a potential rim fragment. While tea cups came standard with a set of dishes, not every settler drank tea. These cups could have been used for many different beverages.

A black on pink hand painted 5 in. whiteware saucer is also represented in the collection. Due to the amount of small and missing fragments and the fact that some of the pieces have been heat altered, the saucer is only partially reconstructed. No maker's marks have been identified with this pattern.

Only one dinner size plate (approximately 10-10 ½ in) was positively identified out of the entire collection. The plate is heavily fragmented, but appears to be a white, plain dish, exhibiting a small ribbed edge along the interior rim. The pattern remains unknown. The plate type is presumably whiteware, but no marks were found on the base to aid in the analysis. However, after 1820, plain, undecorated whiteware often with molded rims became increasingly commonplace. By 1840, this type of whiteware was the cheapest table service available and could be readily found in most American households (Esarey 1982:186).

Discussion

Three ware types are represented at the Beaver Creek Crossing Site: stoneware, ironstone, and whiteware. These were typically inexpensive, durable wares used for utilitarian purposes. The fact that elaborately decorated, high-dollar wares, like porcelain, were not present in the collection, suggests that they were not present at the site. Interestingly, the collection includes several luncheon sized plates and only one dinner plate. From the vessels represented, it appears that functionality, in regards to household ceramics, was of most importance to the early pioneers.

Conclusion

The ceramics at Beaver Crossing tell us many things. From the spatial distribution, a definite pattern can be seen in the location of the artifacts across the site. The number of ceramic sherds that refit, and the generally similar appearance of many of the sherds, represent a low minimum vessel count at the site. This could indicate that few ceramics were broken at the site and that ceramics were moved, or salvaged, when the location was abandoned. The discussion of ware and vessel types shows a thrifty occupation with the utilization of cheap and durable ware types. Overall, the ceramic artifacts have much to tell about the occupants of the site and more research will be done in the future.

References

Bieringer, Ernie, and Bev Bieringer

2001 White Ironstone China: Plate Identification Guide 1840-1890. Schiffer Publishing Ltd., Atglen.

Esarey, Mark Edward

1982 Archaeological Geographical And Historical Comparison. Eleven Nineteenth-

Century Archaeological Sites Near Belleville. Unpublished Master's thesis, Illinois State

University, Normal.

Greer, Georgeanna

1981 American Stonewares: The Art and Craft of Utilitarian

Potters. Schiffer Publishing Ltd., Exton.

Stelle, Lenville

2001 An Archaeological Guide to Historic Artifacts of the Upper Sangamon Basin. Center for Social Research,

Parkland College, Champaign. Electronic document, http://virtual.parkland.edu/lstelle1/len/archguide/documents/arcguide.htm.

Waterman, John Henry

1927 General History of Seward County. Beaver Crossing, Nebraska.

Wetherbee, Jean

1981 A Look at White Ironstone. Wallace-Homestead Book Co., Des Moines.

1996 White Ironstone: A Collector's Guide. Antique Trader Books, Dubuque, Illionis.